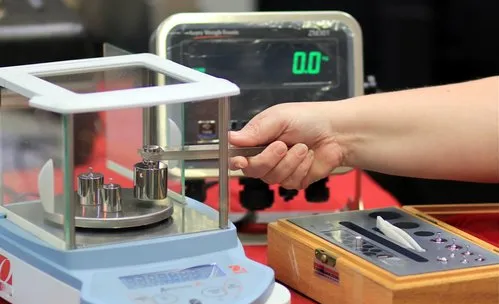

The Importance of Regular Maintenance and Calibration for Optimal Performance of Electronic Weighing Scale

In today’s fast-paced business environment, accuracy and precision are paramount. Whether you’re in the jewellery industry, running a laboratory, managing a retail store, or operating a manufacturing facility, the reliability of your weighing scales is crucial. Digital weighing machines have become indispensable tools, offering efficiency and accuracy in measuring everything from precious metals to bulk commodities. However, to ensure consistent accuracy, regular calibration and maintenance are essential.

Understanding Calibration:

Calibration is the process of adjusting a weighing scale to ensure it provides accurate and reliable measurements. Over time, factors such as wear and tear, environmental conditions, and usage can affect the performance of a scale, leading to inaccuracies. Calibration corrects these deviations, bringing the scale back to its specified accuracy level.

The Benefits of Calibration:

- Accuracy: Calibration ensures that the readings provided by your weighing scale are precise, helping you to deliver Accurate in measurements.

- Compliance: Many industries have regulatory standards that require weighing scales to be calibrated regularly to maintain compliance of Legal metrology department

- Quality Control: Calibrated scales are essential for maintaining consistent product quality and meeting customer expectations to increase your profit

- Cost Savings: Accurate measurements prevent costly errors such as overfilling containers or underestimating product quantities to gain customer Good will

- Longevity: Regular calibration and maintenance can extend the lifespan of your weighing scale, reducing the need for premature replacements.

Frequency of Calibration:

The frequency of calibration depends on several factors, including the type of scale, its usage, environmental conditions, and industry regulations. Generally, high-precision scales used in critical applications may require more frequent calibration compared to scales used for non-critical purposes. It’s important to consult the manufacturer’s recommendations and industry standards to determine the appropriate calibration interval for your weighing scale.

Scale Maintenance Tips:

In addition to calibration, proper maintenance is essential for ensuring the longevity and performance of your weighing scale. Here are some maintenance tips to keep your scale in top condition:

- Keep it Clean: Regularly clean the weighing platform and surrounding area to prevent dust and debris buildup.

- Handle with Care: Avoid rough handling or dropping the scale, as this can damage internal components.

- Avoid Overloading: Never exceeds the maximum capacity of the scale, as this can affect its accuracy and cause damage.

- Check for Damage: Inspect the scale for any signs of damage or wear, such as cracks, dents, or loose parts.

- Regular Inspection: Periodically inspect the scale for accuracy by testing it with known weights or calibration standards.

Conclusion:

In conclusion, regular calibration and maintenance are essential practices for ensuring the accuracy, reliability, and longevity of your weighing scales. By investing in proper calibration procedures and following maintenance best practices, you can optimize the performance of your digital weighing machines, minimize downtime, and safeguard your business against costly errors. Remember, when it comes to precision measurement, accuracy is key, and calibration is the pathway to achieving it.

Accurate: Your Pathway to Profitability!!!