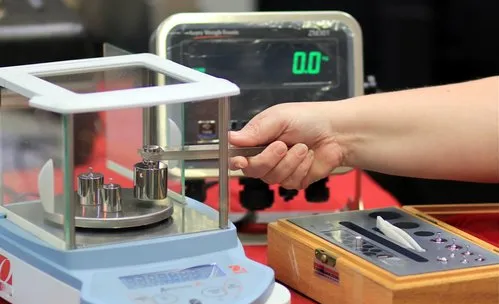

When it comes to obtaining accurate and precise weight measurements, the warm-up time of a weighing machine is often overlooked. However, allowing sufficient warm-up time is critical for ensuring the reliability and consistency of weight readings. In this blog post, we’ll explore the importance of warm-up time for weighing machines and why it’s essential for achieving accurate results in various applications.

Understanding Warm-Up Time

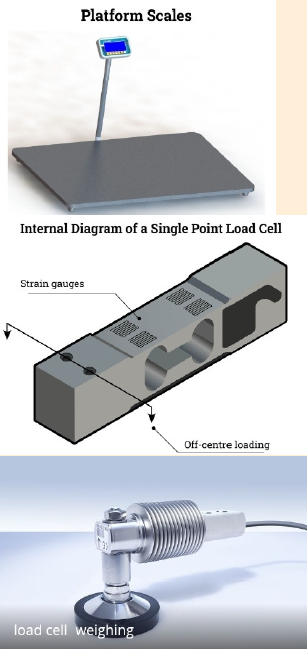

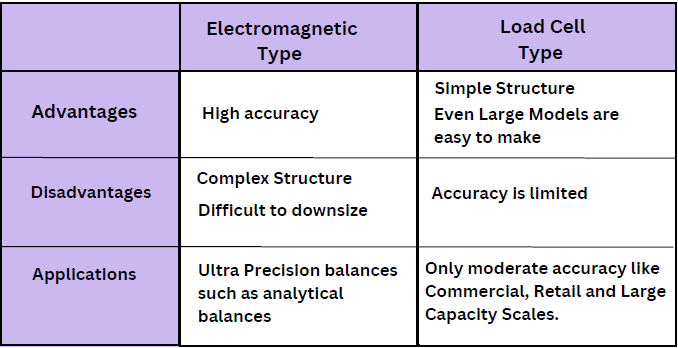

Warm-up time refers to the period required for a weighing machine to stabilize and reach its optimal operating conditions. During this time, the internal components of the weighing machine, such as the load cell and electronics, adjust to the surrounding environment, including temperature fluctuations and mechanical stresses. Failure to allow adequate warm-up time can lead to inaccurate readings and measurement errors.

Temperature Stability

Temperature variations can significantly impact the accuracy of weighing machines, particularly those with sensitive electronic components. As the temperature of the environment changes, the properties of materials within the weighing machine, such as the load cell and circuitry, may also fluctuate. Allowing sufficient warm-up time enables these components to reach thermal equilibrium, minimizing the effects of temperature-related drift on weight measurements.

Mechanical Stability

In addition to temperature stability, mechanical stability is another crucial factor affected by warm-up time. Mechanical stresses, such as vibrations and mechanical shocks, can disrupt the balance and alignment of the weighing machine’s components, leading to fluctuations in weight readings. Allowing the weighing machine to stabilize during the warm-up period helps mitigate these mechanical effects and ensures consistent performance.

Ensuring Accuracy and Precision

The primary goal of allowing warm-up time for weighing machines is to ensure accuracy and precision in weight measurements. By allowing the machine to stabilize before taking measurements, users can minimize the influence of environmental factors and mechanical disturbances on the accuracy of readings. This is especially important in applications where precise measurements are critical, such as laboratory research, pharmaceutical manufacturing, and quality control processes.

Recommended Warm-Up Times

The warm-up time required for a weighing machine can vary depending on factors such as the type of scale, its design, and the operating environment. In general, manufacturers provide guidelines or specifications regarding the recommended warm-up time for their weighing machines. It’s essential to follow these recommendations closely to ensure optimal performance and accuracy.

Conclusion

In conclusion, the warm-up time of a weighing machine is a crucial factor that directly impacts the accuracy and precision of weight measurements. Allowing sufficient warm-up time enables the machine to stabilize, adjust to environmental conditions, and mitigate the effects of temperature variations and mechanical stresses. By following manufacturer recommendations and allowing adequate warm-up time before taking measurements, users can ensure reliable and consistent results in a wide range of applications.